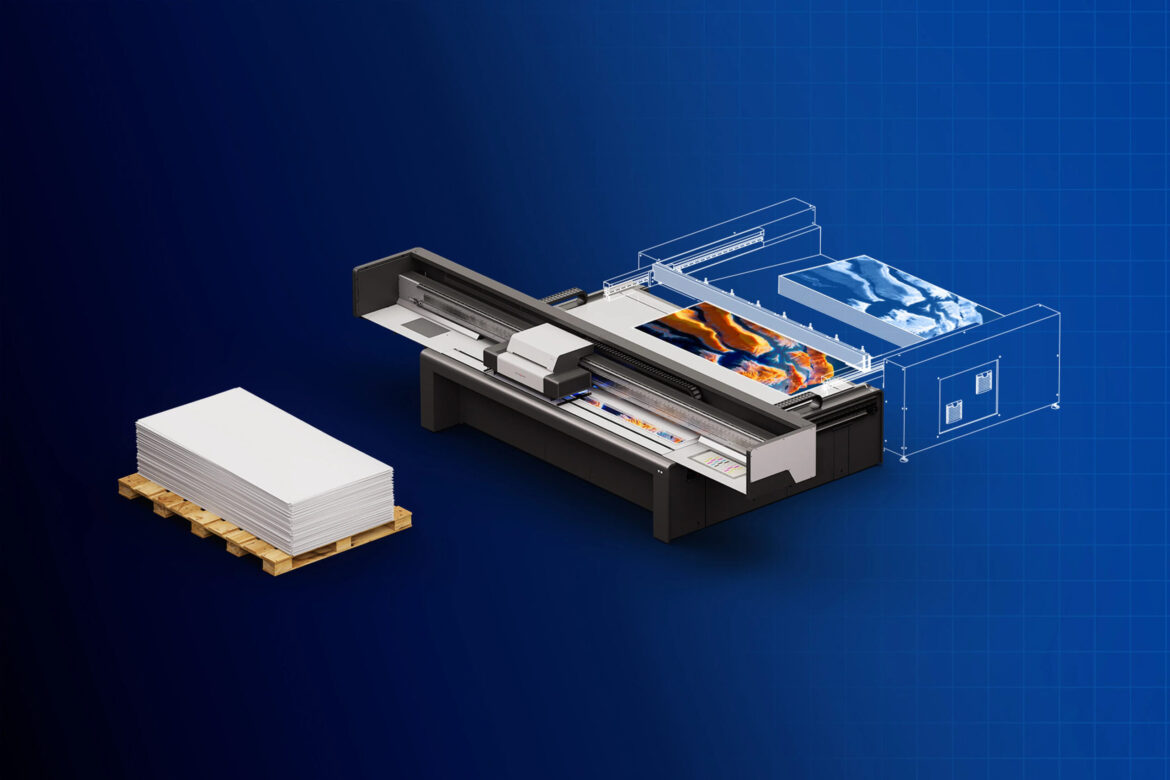

swissQprint presented an automation option at drupa 2024, designed to maintain high productivity in flatbed printing by relieving operators of unloading tasks.

“More and more customers are looking to automate their printing processes while preserving flexibility,” explained Carmen Eicher, Chief of Sales and Marketing Officer at swissQprint. The company has responded to such requests with its initial presentation of an unloading option. The new automation module removes processed media up to 3.2×2 metres from the flatbed printer’s table, the idea being to ease the burden of handling large runs efficiently. Loading continues to be done by hand.

swissQprint gathered initial customer feedback as part of the development process. “drupa is now the perfect opportunity to show the conceptual study and collect broad-based feedback that will go into final development,” said Carmen Eicher. Thus tailored to market needs, the finished product should be available in 2025.

Versatility unaffected or even extended

swissQprint customers appreciate the diversity of applications their machines can handle. The company emphasises that the new unloading option preserves printer versatility and accessibility. Special applications, short runs and roll jobs are doable as before because the unloading option undocks from the printer any time.

Product panorama at the stand

The unloading option complemented a round-up of developments shown by swissQprint in live demos at drupa 2024. First and foremost was Kudu, the high-end flatbed printer featuring top performance at an exceptional quality level. This was the model used to present the unloading option. Also on the stand was Karibu 2, highly efficient and versatile thanks to unique features. And last but not least: Nyala, the swissQprint flagship that for the past nine years has been Europe’s best-selling flatbed printer in its class.

swissQprint also inspired visitors with a wide-ranging application gallery. The neon room proved especially popular.