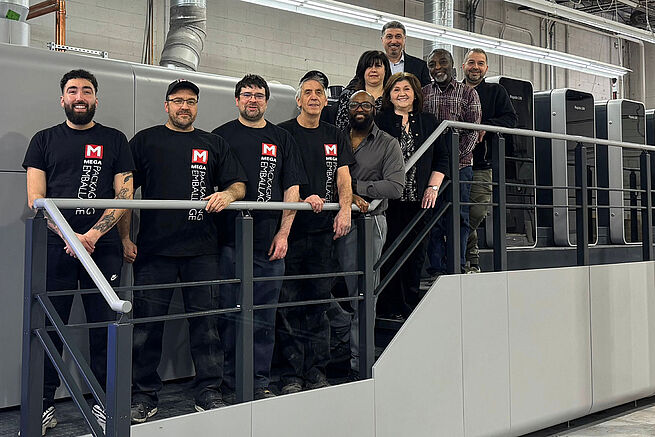

Emballages Mega Packaging, a family-owned mid-size folding carton manufacturer headquartered in Montreal, has reached a significant milestone.

The company has begun full-scale production on its new Koenig & Bauer Rapida 106 six-color hybrid UV press with coater, operating at a top speed of 18,000 sheets per hour.Emballages Mega Packaging proudly serves a variety of North American industries, including food and beverage, medical, pharmaceutical, beauty, and textile. The firm has seen substantial growth due to its commitment to delivering the highest quality folding cartons and exceptional customer service.

“Our new Rapida press provides the versatility to quickly adapt to our customers’ changing needs,” says Marco Macri, President and CEO of Emballages Mega Packaging. “The high level of automation enables fast makereadies and impressive production output, all while maintaining excellent quality. Our partnership with Koenig & Bauer will help us uphold our strong dedication and commitment to our clients.”

At the heart of Mega’s new Rapida 106 is its impressive speed, superior quality, and advanced automation. The press can handle board thicknesses up to 48 pt and is equipped with a fully automatic logistics system for continuous running on the thickest materials.

To maintain color quality and efficiency, the press features the QualiTronic ColorControl inline color control system and fast makeready tools with unbent printing plates. Mega’s customers also benefit from the Rapida’s full QualiTronic PDF inline image inspection system, which compares every printed sheet to the PDF data from pre-press.

To keep up with the firm’s growth and additional capacity, the press is equipped with Koenig & Bauer’s unique SIS Sensoric Infeed System, which requires no setting and ensures mark-free, reliable feeding. The press also features fully automatic plate changing, real-time performance monitoring, and simultaneous roller washing.

Macri’s team has found the new Rapida 106 to be 50% more efficient, with the firm’s fastest makereadies ever. Since the press arrived, Mega’s team has been impressed with Koenig & Bauer’s customer support, with access to technical assistance, training, and guidance from the manufacturer’s team of experts, local support staff, and Montreal-based technicians.