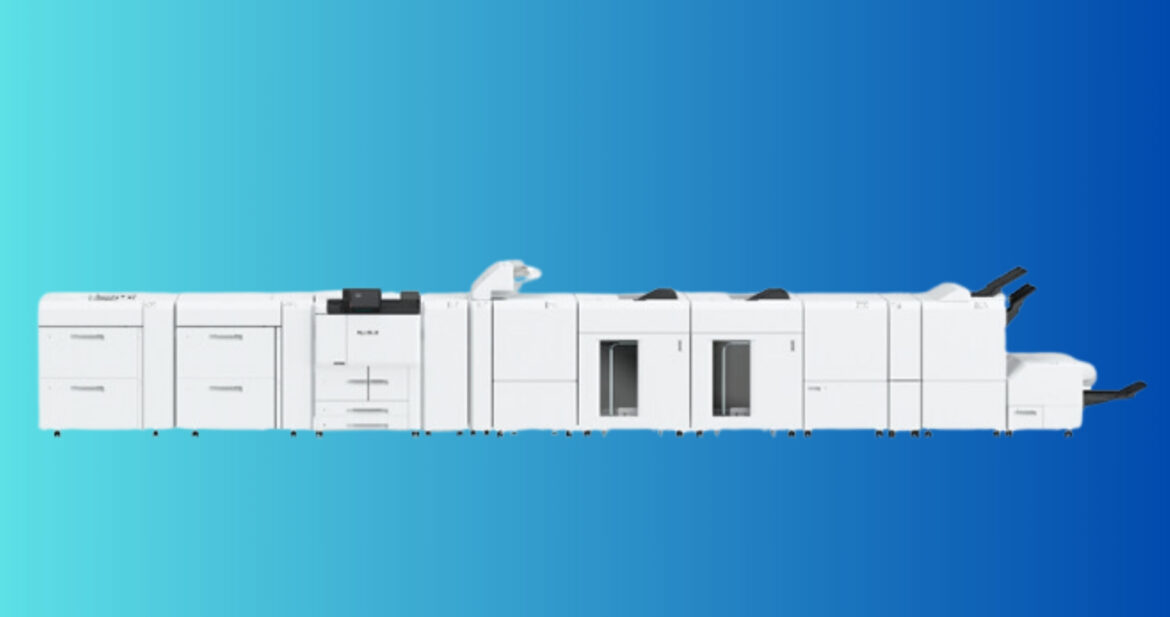

FUJIFILM Business Innovation Asia Pacific announces the launch of Revoria Press E1136P, an advanced monochrome production printer for on-demand printing, catering to professional and institutional environment.

This latest addition to the Revoria Press E1 series*1 , and now all models of the Revoria Press E1 series introduce innovative features as the new options, including the capability to connect two units for dual operation of the High Capacity Feeder*2 and the Air Suction Feeder*2. This advancement facilitates continuous mass printing, significantly enhancing productivity. Additionally, the optional Print Inspection System*2 provides automated quality checks during the printing process, ensuring that defects on the printed materials are promptly detected. Sales of the Revoria Press E1136P and the new options for all models of the Revoria Press E1 series will commence on November 7 across the Asia Pacific region.

Since its release in 2021, the Revoria Press E1 series has garnered positive feedback from users, establishing itself as a trusted solution for on-demand print businesses across various sectors.

The Revoria Press E1 series is a versatile printing solution designed for a wide range of printing needs, particularly in commercial printing and production environments. This series is ideal for business seeking to enhance their printing capabilities with high-quality, high-speed production, and flexible finishing options.

The Revoria Press E1 series excels in producing high-quality marketing materials, manual, reports, and corporate documents for centralised in-house printing departments in corporations. It is also well-suited for high-volume printing jobs, including brochures, catalogues, and direct mail, making it a strong choice for commercial print providers. Furthermore, its capabilities extend to education and training materials, enabling schools and training organisation to create high-quality materials.

Key features of the Revoria Press E1 series include:

- The latest model, Revoria Press E1136P allows for the connection of two units of the High Capacity Feeder and the Air Suction Feeder, as well as the High Capacity Stackers*3. This new continuous paper feeding option reduces the frequency of paper replenishment during large-volume printing, facilitating extended period of operation.

- Print Inspection System: This advance system is compatible with all models in the Revoria Press E1 series. It automatically inspects printed materials in real-time, comparing scanned images against original RIP data to detect defects such as small as 0.3 mm. The system identifies issues such as dots, stains, pinholes, streaks, dog ears, registration misalignment, and variations in colour density. It also ensures the readability of printed barcodes and OCR fonts, confirming that the numbers are sequential and numbers on side 1 and side 2 match.

- Quality Control Alert*4: The printer provides alerts for colour variation and front-to-back misalignment during printing process, enabling operators to maintain consistent print quality. By automatically identifying and reprinting defective materials, the system significantly reduces the operator’s workload and saves time, ultimately enhancing overall print process.