(Ghent, Belgium) Hybrid Software, developer of innovative productivity tools for label & packaging printing, will be displaying its full product portfolio at Labelexpo Americas 2024, Booth 3015. The new PACKZ 10, an all-in-one PDF editor and prepress application for both digital and conventional printing; CLOUDFLOW, the modern workflow engine; ColorLogic’s color management software; SmartDFE™, the only AI-accelerated digital front-end for inline printing of fully variable data; and iC3D photorealistic rendering and prototyping will all be demonstrated. Hybrid Software technology is also incorporated in the offerings of a number of manufacturers of digital label printing presses across the show floor.

Hybrid Software serves a truly hybrid world

Digital presses are here to stay, but conventional printing is not disappearing. Efficient print production requires good manufacturing practices, and the craftsmanship and knowledge of traditional print developed over generations. Converters and printers expect connectivity across all their hardware and software systems, but the IT environment where they operate is challenging and unforgiving. Hybrid Software operates at the nexus of prepress production and cutting-edge IT: The IT experts who know prepress, and the prepress experts who know IT.

Commitment to Innovation

Hybrid Software will be highlighting several new products and technologies at Labelexpo. They include:

Hybrid PACKZ 10: The latest version of Hybrid’s popular all-in-one PDF editor adds new capabilities for both digital and conventional printing, including enhanced 3D visualization and ray tracing for shrink sleeves and die-formed metal cans, utilizing a tight integration of two Hybrid Software products, iC3D and Capture 3D.

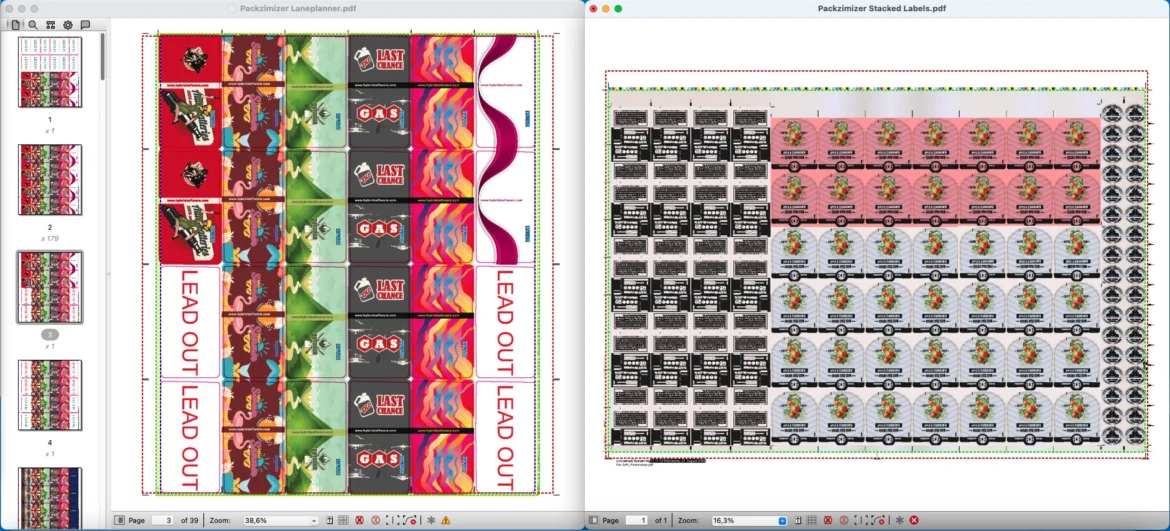

Hybrid Software’s auto layout and step-and-repeat technology for roll-fed digital labels and stack offset printers,Packzimizer, includes new features to manage short print runs and smaller quantities. Packzimizer intelligently analyzes order data to optimize the layout and repetitions of labels on a roll based on quantity, offering maximum substrate usage and press uptime.

Hybrid CLOUDFLOW: Hybrid Software’s highly configurable enterprise production workflow system provides fast and effective automation of prepress tasks for many converters and printers worldwide. MyCLOUDFLOW is a 100% cloud-based SaaS solution running in a dedicated Amazon Web Services (AWS) cluster and supported by Hybrid’s dedicated team of IT professionals, with strong data protection and immutable backups.

CLOUDFLOW’s ProofScope tool for artwork viewing and approval now includes a 3D approval system based on iC3D technology. Users can visualize product labels as well as embellishments like glitter and varnishes, applied directly to three-dimensional shapes including cartons and bottles, accurately distorting artwork to assure the highest quality shrink sleeves.

ColorSpace: Built on technology from Hybrid Software’s ColorLogic business, ColorSpace offers optimized color matching for digital and conventional printing to all users of PACKZ and CLOUDFLOW. ColorSpace supports different color spaces, from process color and extended gamut printing (ECG) to specific brand color inks. It offers non-experts—sales reps, CSRs and others—an automatic selection of the best ink configuration for each job, on a given printing press, based on the smallest deviation from the desired spectral color (∆E), with reporting to MIS/ERP for accurate quoting.

SmartDFE turnkey digital front end (DFE) for digital presses: SmartDFE is targeted for high-speed, single-pass presses printing fully variable data. It is built upon Harlequin Direct™, the world’s fastest PDF RIP, providing rasterization and inkjet drop generation for the best possible image quality and quickest printing speeds. It offers independence from third-party core RIP solutions, relying on Hybrid’s own Harlequin Core™—the world’s fastest RIP core—as well as workflow technology based on CLOUDFLOW, and color management from ColorLogic – all developed in-house. SmartDFE is used to power a number of digital label presses that are displayed at Labelexpo, although it is often marketed and sold under Hybrid Software OEM customers’ own brand names.

Hybrid Software has maintained its focus on building the most productive tools for label and packaging printers and converters. “All Hybrid Software companies have one common mission: We are the heartbeat of industrial printing and packaging, whether flexo, offset or digital printing. For example, we are the only company that can drive any digital press with technology developed 100% in-house. This includes all the tasks required to manufacture print, from file preflighting and ink estimation, to prepress workflow and layout, to all facets of color management, RIPping files to a digital printer, overseeing inkjet printhead performance, to analyzing and reporting to networked MIS/ERP solutions,” explains Mike Agness, Hybrid Software Executive Vice President, Americas. “Yet, just as important as our technology is that we care, on a very local level, about our customers’ successes.”